References

LAKASA Auto-Dosing Unit (ADU)

LAKASA Auto-Dosing Unit (ADU) is highly recommended to install in conjunction with grease interceptor. It will ensure the dosing of biomatic liquid enzyme at regular intervals consistently. It enhances the efficiency of the operation and significantly reducing the build-up of grease and frequency of cleaning.

There is a digital timer to control setting for the dosage and timing of dosing the biomatic enzyme. The reliability and accuracy for the timing and dosage setting is important and critical, because this will ensure the optimum performance of the enzyme and to avoid the wastage of enzyme

There is a Back-up battery for the setting in case of power failure. The setting of the programs will still be valid and when the power supply is resumed. The auto-dosing system will continue to run as normal and do not have to re-set again.

Specification of LAKASA Auto-Dosing Unit

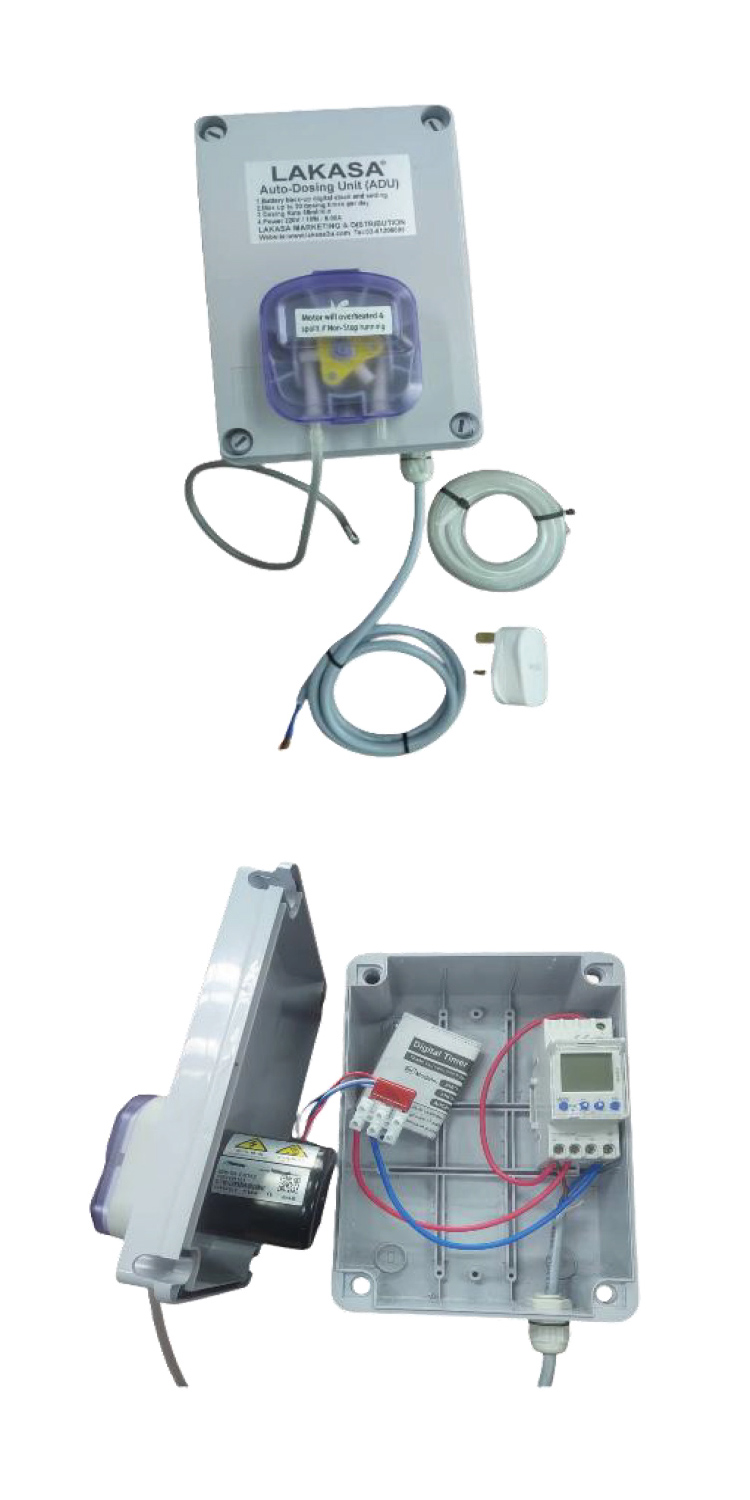

The unit is a temporized dosing system, activated by a programmable digital timer. It comprises and completed with

- PVC Enclosure Box, size 8”x6”x3” (IP 66)

- Peristaltic Dosing Pump

- Digital Timer with Litium Battery backup to 3 years memory / program without power connection. No usage of Litium Battery when there is power supply.

- 2 meter electric cable wiring

- 0 meter length (6mm OD, 4mm ID) flexible silicone enzyme supply hose,

- 400mm length (6mm OD, 4mm ID) flexible silicone sucking hose

- Anti-float weight (stainless steel 304), which prevent hose from floating on the liquid surface, ensuring proper sucking

- 3 pin plug,

| Motor Type | 220V Synchronous Motor |

| Power | 18 Watt |

| Rated Voltage / Current | 220V / 0.08A |

| Control Method | Switch Control |

| Weight | Approx 803g |

| Noise | <65dB |

| Motor Life Span | 800 operating hours |

| Perilstatic Tube Material | BPT Pump Tube |

| Perilstatic Tube Life Span | 1,000 operating hours |

| Perilstatic Tube Diameter | 6.4mm OD, 3.2mm ID |

| Flow Rate | 68 ml / minute |

| Note : BPT Pump Tube resistance to common chemical, acid and alkali, and oxidation resistance | |

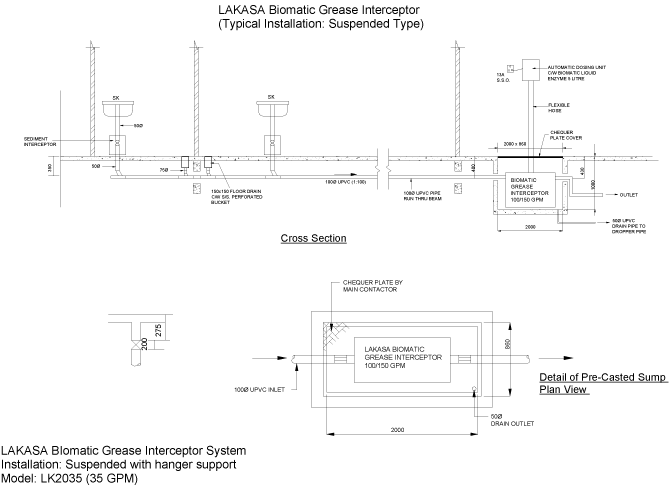

Installation

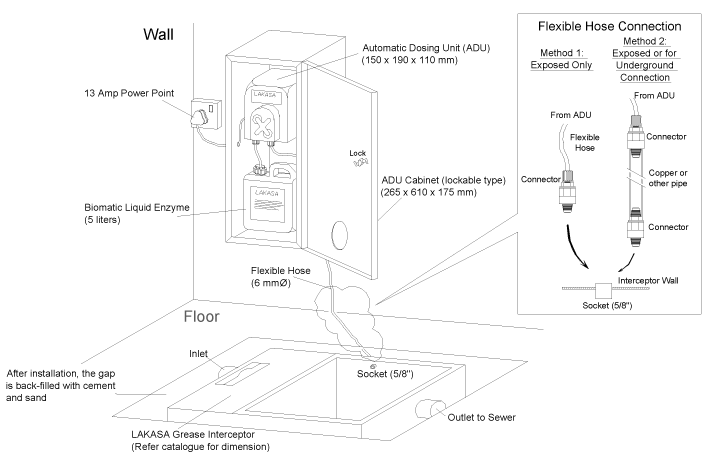

The LAKASA ADU is recommended to be located in close proximity to the grease interceptor. The recommended distance is not more than 5 meters for effective transmission horizon length and less than 2 meters vertical height above the enzyme source to the destination.

A conduit pipe (>8mm ID) to safeguard the enzyme silicone supply hose (6mm OD) is recommended to link the auto-dosing pump to the grease interceptor.

Operating Instruction for ADU

- Connect the ADU to a 13 amp power point.

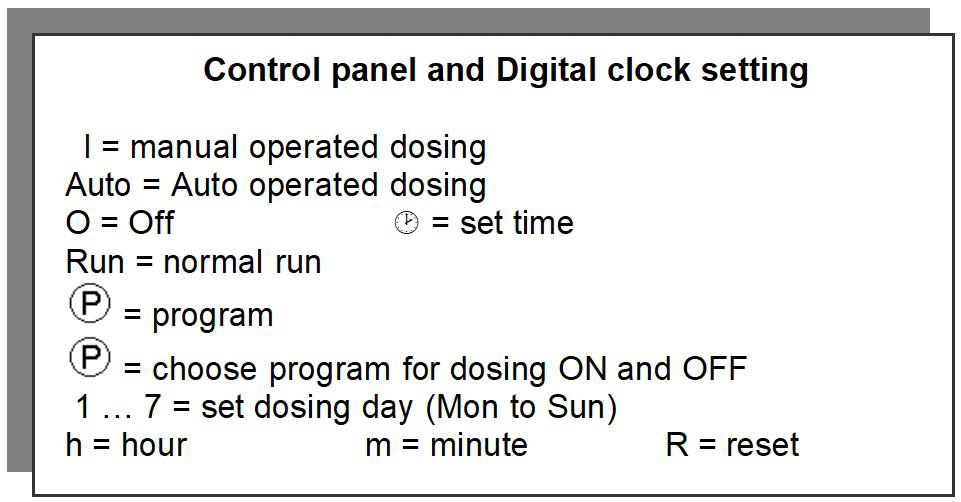

- Set the current time at the digital clock.

- Set the dosing ‘ON’ time (2 hours after the kitchen is closed) and the dosing ‘OFF’ time for a correct dosing duration according to recommended enzyme dosage.

- Run manual dosing with the initial dosage and to ensure the ADU is running properly.

LAKASA Auto-Dosing Unit (ADU) is installed close proximity to Grease Interceptor

Installation for LAKASA Grease and Sediment Interceptor & Grating Sediment Trap

Method Statement for Installation of LAKASA Biomatic Grease Interceptor, Auto-Dosing Unit and Biomatic Enzyme

Grease Interceptor

- Inspect unit for defects or damages and make sure it meets specified requirements (eg : model and size).

- Inlet & outlet is connected accordingly and properly. DO NOT INSTALL INTERCEPTOR BACKWARDS. Place at a firm & balance concrete base. Install interceptor as close as possible to the source of fats, oils and grease (FOG) laden water. This minimizes unprotected pipe, and FOG separates best when effluent is relatively hot.

- Install interceptor sitting on floor, partially recessed or flush-to-floor, making sure there is enough room to allow for easy maintenance of the unit. (Room for cover to be removed and sediment bucket to be taken out for cleaning).

- INTERCEPTOR MUST BE PLACED ON A FLAT, SOLID SURFACE TO SUPPORT THE BOTTOM! When suspending interceptor from floor above, all units must be fully supported on bottom with a flat surface strong enough to support the weight of the unit when full of water/FOG. All units must be independently supported to avoid stress on fittings.

- WHEN INSTALLING IN THE GROUND, Construct a solid manhole sump for housing the interceptor. Manhole sump cover should normally be higher a bit the floor level OR construct a drain surrounding the cover to channel away most rain water and prevent in from entering the sump. The sump should also allocate four corner water exit at lowest possible 4 sides corners for the in case splashed into rain water to escape and seep into the earth outside the sump.

- FILL INTERCEPTOR WITH WATER AND INSTALL LID BEFORE BACK FILLING. It is recommended to use light sand for back fill. Be sure backfill is free of sharp stones and foreign matter to avoid punctures. (DO NOT PUT SAND IN INTEREPTOR!)

- INTERCEPTOR filled with clean water until static water level and is ready for operation.

Auto-Dosing Unit (ADU)

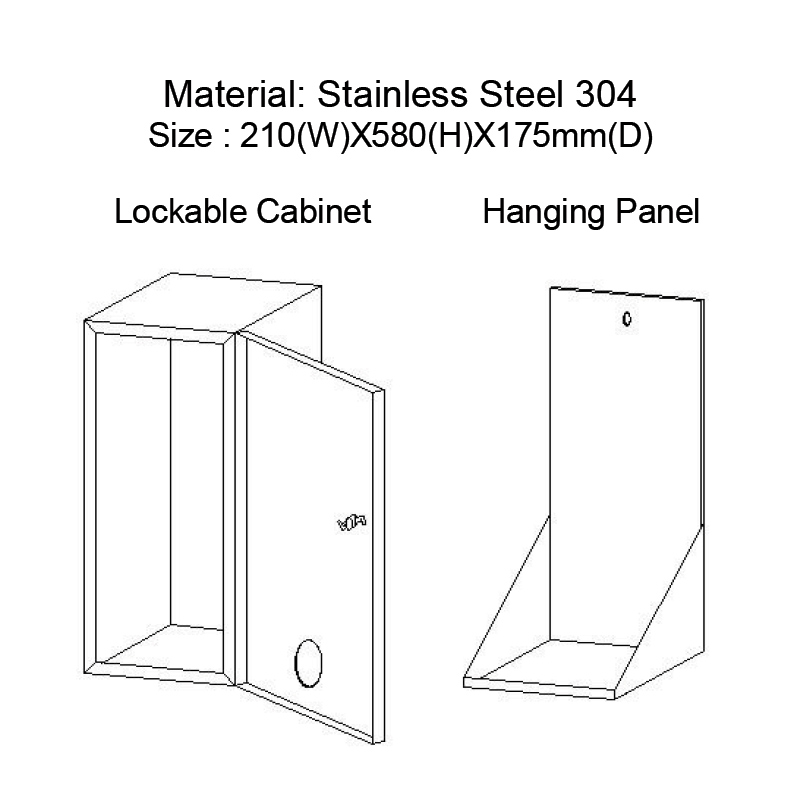

- To mount the ADU to wall with a lockable cabinet.

- To connect ADU to a 13 Amp power point.

- To set current time and dosing time (set 1 hour after kitchen close).

- To set the dosing duration according to recommended dosage. The unit is running at a speed of 7 ml/min.

- To connect a short flexible hose to enzyme bottle. Use steel weight and strainer provided to ensure the hose reaches the bottom of the bottle.

- To connect a long hose (with conduit pipe) to the grease interceptor. To use the connector provided to join the connection.

- To switch to manual dose to ensure pump head is rotating and enzyme is sucked up and delivered to interceptor.

- To switch to “Auto” and the ADU will run automatically according to the preset time.

Biomatic Enzyme

- Avoid direct sunlight and should be kept inside the ADU cabinet.

- When biomatic enzyme level is running low, replenish and top up as soon as possible.