References

LAKASA LINT INTERCEPTOR (Wool Interceptor)

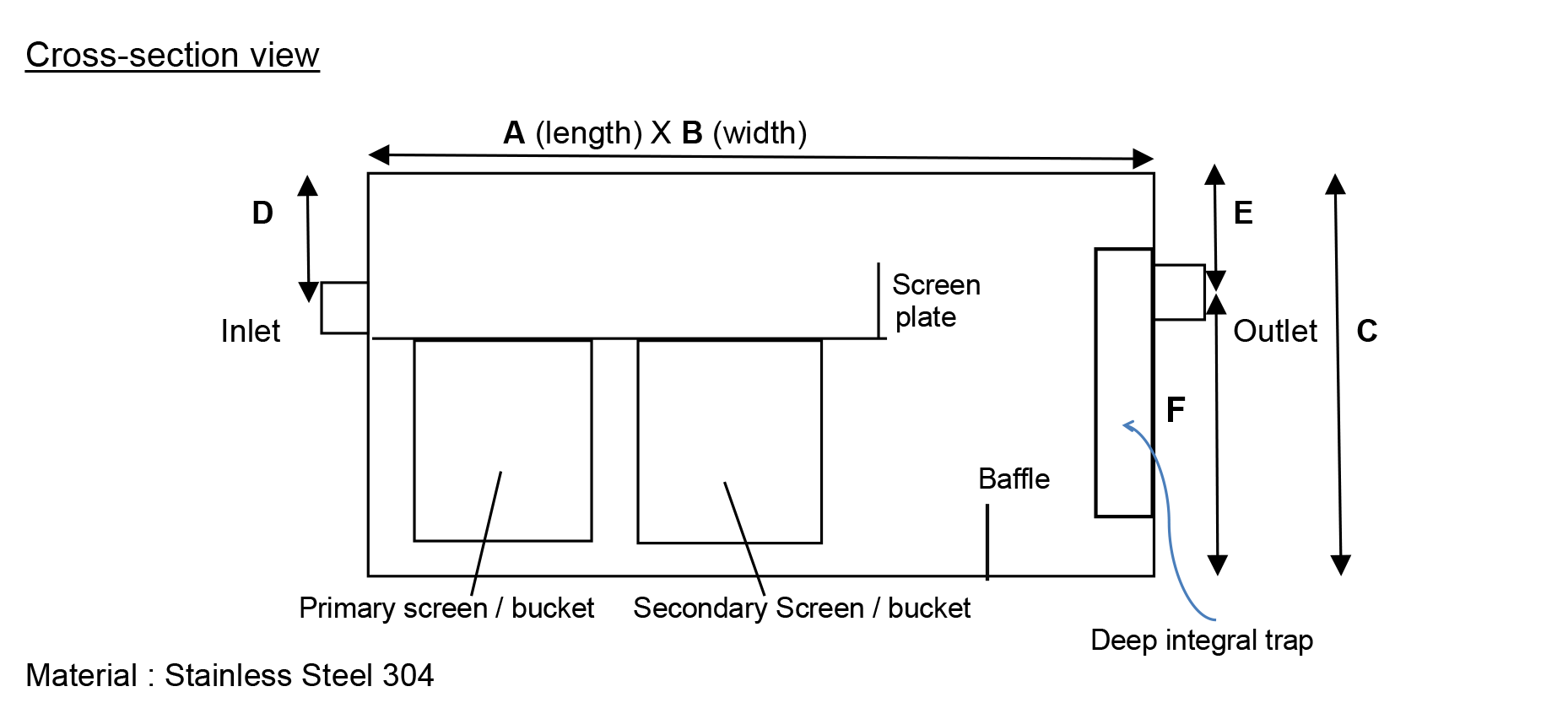

LAKASA Stainless Steel Lint Interceptor or Wool Interceptor is designed for commercial applications such as Laundromats, hotels, motels, nursing homes, hospitals etc. LAKASA Lint Interceptor will separate and retain solids like buttons, stones, string and lint, which prevent the drain lines from blockage with those solid particles.

The interception process is achieved through the concept and the principle of gravity separation. The velocity and turbulence of the incoming water is reduced and directed downwards. This helps and facilitates the settlement of the heavy sand and solid particles to the bottom level at the primary screen / bucket. Some lint will float to the surface. The bigger and heavier buttons, stones, etc will be retained in the first bucket, while smaller and lighter particles, such as string and lint, will be trapped in the second bucket.

The Interceptor is equipped 3/8” diameter perforation removable screen, which prevent the passage into the drainage system of solids 0.5 inch (12.7mm) or larger in size, string, rags, button or other material detrimental to the public sewerage system (1003.6 International Plumbing Code 2003)

The cleaning and maintenance routine of both the primary and secondary screen / bucket should be scheduled according to the volume of the lint and other solids content in the daily waste water. It can be daily, weekly or monthly. During initial period of operation, monitor more regularly to establish the frequency of maintenance required for the particular application. The efficiency of operation directly related to the level of maintenance.

Sizing criteria : The system must be of adequate size and design to allow for cool-down of waster water so that the separation can be more readily achieved. Designed to achieve a minimum Water Retention Time (WRT) of 1 minute (with average WRT thru-out the day normally more than 30 minutes. This will be achieved when the pattern of water flow is in intermittent manner) for satisfactory removal Percentage and avoid overflow during peak flow of incoming waste water.

| Model | Flowrate

(GPM) |

Inlet & Outlet | A

(length) |

B

(width) |

C

(height) |

D | E | F |

| LL6025 | 25 | 75 | 750 | 450 | 500 | 100 | 120 | 380 |

| LL6035 | 35 | 75 | 800 | 500 | 550 | 100 | 120 | 430 |

| LL6050 | 50 | 100 | 900 | 550 | 600 | 110 | 130 | 470 |

| LL6075 | 75 | 100 | 1100 | 600 | 640 | 110 | 130 | 510 |

| LL6100 | 100 | 100 | 1220 | 650 | 720 | 130 | 150 | 570 |

| LL6200 | 200 | 150 | 1650 | 780 | 890 | 150 | 180 | 710 |

| LL6300 | 300 | 150 | 2050 | 860 | 980 | 160 | 200 | 780 |

| LL6400 | 400 | 150 | 2200 | 950 | 1080 | 180 | 210 | 870 |

| LL6500 | 500 | 150 | 2440 | 1020 | 1140 | 180 | 210 | 930 |